STRIKING A BALANCE

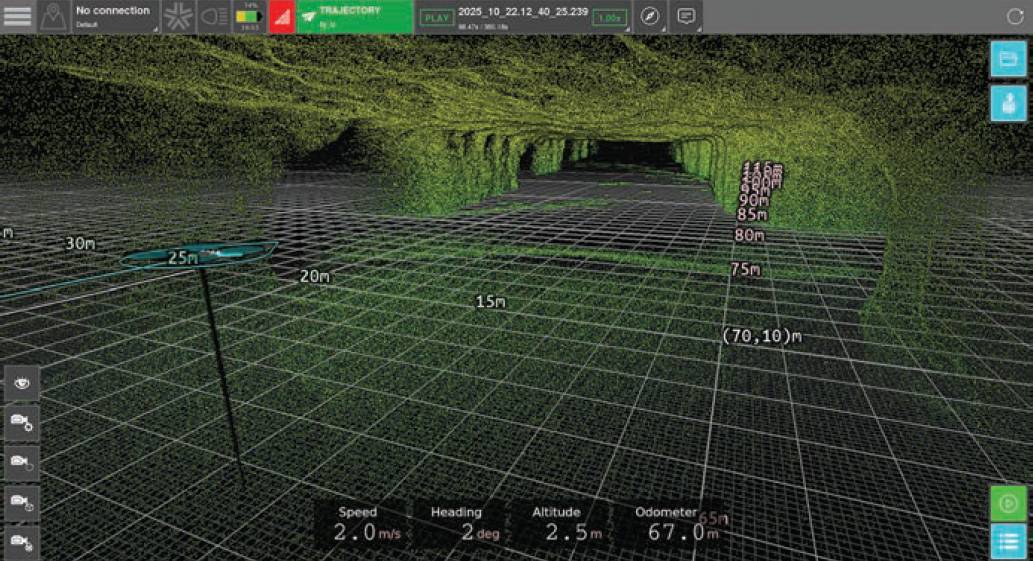

Typical Nexys generated data.

A five-day survey cut down to half a day

A strong understanding of the Exyn Nexys SLAM technology enabled Systra UK to strike a balance between speed and accuracy during a recent structural assessment survey of a large and complex building in Manchester.

In the heart of Manchester’s busy city centre, a historic building on a well-used thoroughfare is set to undergo structural alterations. From a surveying perspective, the site presented numerous challenges for the appointed contractor, Systra UK. Architecturally complex, the building comprises a mixture of small and large rooms, irregular geometries, long corridors, varying floor levels and extensive internal clutter including scaffolding and temporary supports.

While parts of the building stand vacant, other areas remain fully operational, occupied by office staff. The client requested minimal disruption in these main areas throughout the survey, a requirement that risked limiting access times, particularly if multiple instrument setups and heavy tripods were needed. For the Systra UK team, led by senior survey manager Tomek Koniuszy, a further challenge lay in meeting a tight deadline to produce a comprehensive point cloud. This dataset would underpin the creation of an accurate floor plan and a detailed structural assessment survey and serve as a baseline for future works.

Example of live fast colourisation of the Exyn Nexys Pro point cloud data from another project.

While assured that he could create a high-quality millimetre-accurate point cloud with a laser scanner, Tomek was aware that this could take up to five days and disrupt the occupants with the placement of targets and multiple time-consuming setups of the building. With all the internal scaffolding, shadowing could also be an issue because it was imperative that the point cloud was clean.

Consequently, a SLAM system was considered for deployment due to the balance between its advantages – notably speed and flexibility – and the level of accuracy it could achieve. However, some initial challenges were anticipated, such as convincing a client accustomed to working to millimetre tolerances for high-accuracy survey and rail applications to adopt a workflow designed to deliver less accurate data, although still within the project’s requirements.

Seeking more information about the technology, Tomek conducted online research into potential SLAM systems and soon came across KOREC’s newly announced partnership with Exyn Technologies and its Nexys modular 3D mapping solution. After a brief demonstration, the decision was made to proceed with the system. Data ownership was also key to this decision; he expressed the importance of owning data, rather than giving access to a third party.

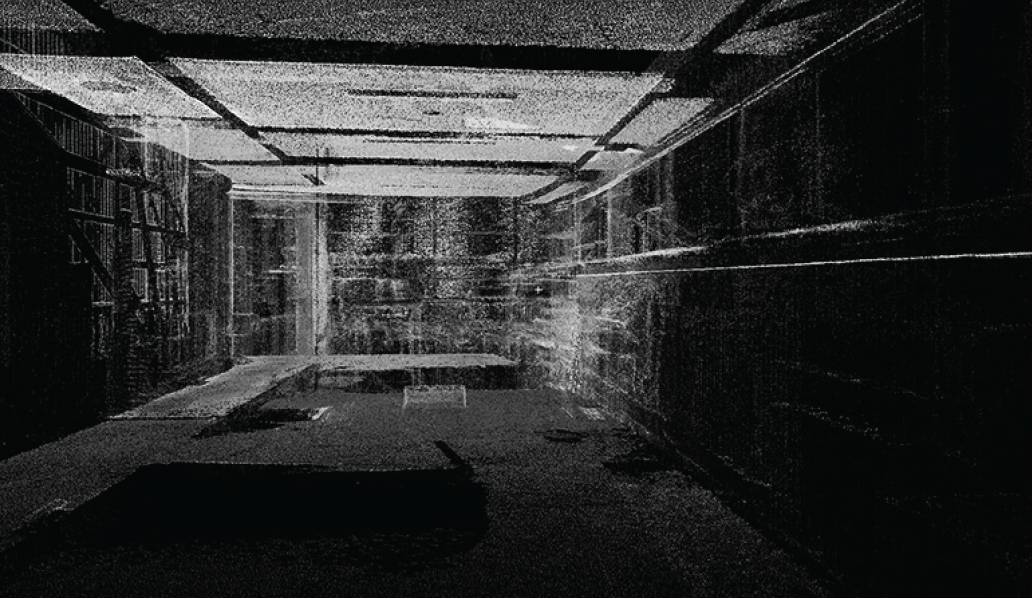

Data captured with the Nexys showing di›erent floor levels.

Before the building was surveyed, control was established outside, rather than inside, which the Systra UK team felt was a notable gain. This was backed up by retro targets around the entry and exit points.

Further accuracy validation was achieved through common points identified between the terrestrial scans.

A Systra UK surveyor, with a member of the KOREC team advising, then completed the survey using the Nexys system in half a day, rather than the five days estimated for the use of a laser scanner. This efficiency was further enhanced by the system’s ability to display scans in real time, allowing the team to verify completeness in the field and minimise the need for rework.

Once in the building, it was possible to go anywhere with minimal disruption to the occupants – behind a wall, under a table, down dead ends, along corridors; anywhere. Capturing all the data needed for a clean shadow-free point cloud couldn’t have been easier.

The captured data was then processed with the assistance of KOREC. Accuracy assurance for the client was provided by reporting on previously coordinated scanning targets positioned around the building. These control targets were registered by the Nexys within a range of 5mm to 20mm in 3D when compared with the terrestrial scans. This was deemed sufficiently accurate for the project’s requirements. Further accuracy validation was achieved through common points identified between the terrestrial scans (based on survey control) and the Nexys point cloud.

The Nexys technology allows the control to be adjusyed but it was decided that this was not necessary having achieved an excellent result considering the type of technology employed.

Finally, the client carried out an in-depth review of the dataset, confirming the overall reliability and precision of the results.

The advantages delivered by the Nexys system on this project outweighed the loss of using a static scanner and achieving a millimetre-accurate point cloud. Scans could be done 20 times faster than a terrestrial scanner at the expense of around 15mm of accuracy.

Data captured with the Nexys showing stairways.

The key benefits included:

- The entire building was surveyed in just half a day, compared with the five days estimated for a traditional laser scanning approach.

- Accuracies were within the required tolerance with minimal drift (±1 cm accuracy, environment-dependent and refers to spatial mapping precision for 3D point clouds, not raw sensor range).

- Minimal disruption to occupants, allowing the survey to be completed during normal working hours.

- Little to no shadowing, resulting in a clean, comprehensive point cloud.

- The technology proved extremely intuitive and easy to master.

- Exceptional versatility and speed, even within the building’s complex layout.

The client responded positively to the demonstration of how the point cloud data had been captured, and the Nexys proved an excellent solution while working under tight time constraints.

Not every project requires millimetre-level accuracy. In this case, there was a compelling reason to use a slightly less precise platform. In short, it truly made the difference between make or break for Systra.