Streamlining nuclear power plant construction

Paul Challis, Topcon

IN the UK, we currently generate around 15-20 % of our electricity from nuclear energy. To support the UK government commitment to reach net zero emissions by 2050, Hinkley Point C in Somerset is under construction. This is the first new nuclear power station to be built in the UK in more than 20 years and will provide low-carbon electricity for around six million homes. The electricity generated by its two EPR reactors will offset nine million tonnes of carbon dioxide emissions a year, or 600 million tonnes over its 60-year lifespan.

As part of the project, Balfour Beatty is responsible for delivering the complex marine and tunnelling works, and constructing the structures for the critical infrastructure needed to supply cooling water to the power station. This project involves the construction of three tunnels under the Bristol Channel, with offshore concrete heads allowing sea water to pass into the tunnels.

Building on its partnership, Balfour Beatty used the Topcon ClearEdge3D Verity software system to ensure that a key part of the project was completed accurately, on time and on budget.

Through the delivery stages from design to offshore execution, precision was vital with very tight construction tolerances required.Working within tight tolerances

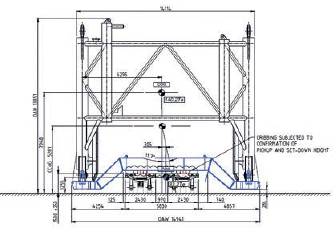

Through the delivery stages from design to offshore execution, precision was vital with very tight construction tolerances required. Once complete, the system will be connected to the seabed via vertical shafts, capped with intake and outfall heads. The intake structures are 44m long, which is roughly the length of four double-decker buses, and around 8m high, weighing more than 5,000 tonnes each.

These structures were constructed at Balfour Beatty’s site in Avonmouth, Bristol. Large steel alignment frames were then installed on top of the heads to enable future lifting and piling operations. Lifting lugs were cast into the reinforced concrete heads and these were then matched against handling frames. The accuracy of the fit was critical due to the 5mm tolerance available for alignment, ultimately allowing for the installation of the lifting pins and the subsequent safe offshore lifts.

Balfour Beatty’s digital project delivery coordinator, Tom Bush explained that using cranes to rotate and position the large fabricated structures on to the concrete heads was an incredibly challenging task. There was no room for error. While the concrete heads were being constructed, fabricators were building the alignment frames and with such a small tolerance on either side of the lifting lugs, the data and measurements provided needed to be accurate.

Verification of works

Using the ClearEdge3D Verity software, point cloud data could be compared with design and fabrication models for verification of the work. The software enabled them to compare real-time data being supplied by the survey team on-site, against initial drawings, to ensure the lifting lugs were aligned with the tolerance available. Inaccuracies were discovered during the first comparisons, and so changes were fed back to the fabricators and rectified early on.

Topcon’s software was also used to run several scenarios and create a digitally accurate approach. The software translated data collected on-site into a digital model, providing demonstrations of the rotations and twists of the installed lifting lugs on each of the heads, with access to the latest data.

Tom Bush said that the ability to accurately verify the position of each individual lifting lug on each of the concrete heads gave them the as-built information to fabricate and fit the alignment frames.

Paul Challis, Topcon