A TWO-TIERED APPROACH

Capturing data from Exeter’s streets while surveying the city’s hidden history proves a worthy challenge

A request to survey a 390m network of Exeter’s historic underground tunnels – some as narrow as 430mm – and to tie those tunnels to the topography of the streets above presented exactly the kind of complex, technical challenge that Benchmark Surveys excels at. This heritage project was delivered successfully through the use of a fully integrated Trimble workflow.

At the manhole site, the Trimble X7 3D laser scanner was used on an inverted tripod to link the above and below ground surveys.

As the people of Exeter go about their daily business along the streets of the city, most are unaware that beneath their feet, in some cases just 710mm beneath, a network of historical tunnels, dating back to medieval times, runs through the area.

Constructed primarily in the 14th century, these passages were designed to house lead pipes that transported fresh drinking water from natural springs nearby into the walled city.

A fine example of the advanced engineering of the time, the tunnels allowed for easier maintenance and repair of the pipes without the need to dig up streets.

Since then, the passages have become historically important to many major events associated with the city, from wars to sieges, and are the only ones of their kind open to the public in the UK.

For Exeter-based Benchmark Surveys, the task of creating a highly accurate floor plan of all the tunnels – and placing them in context with the topography above – has been both professionally and personally rewarding, especially for the company’s director, James Richards.

The initial brief from Exeter Council was to capture both 2D and 3D data of the tunnels, enabling the production of sectional drawings, a floor plan and a DWG-format topographic survey.

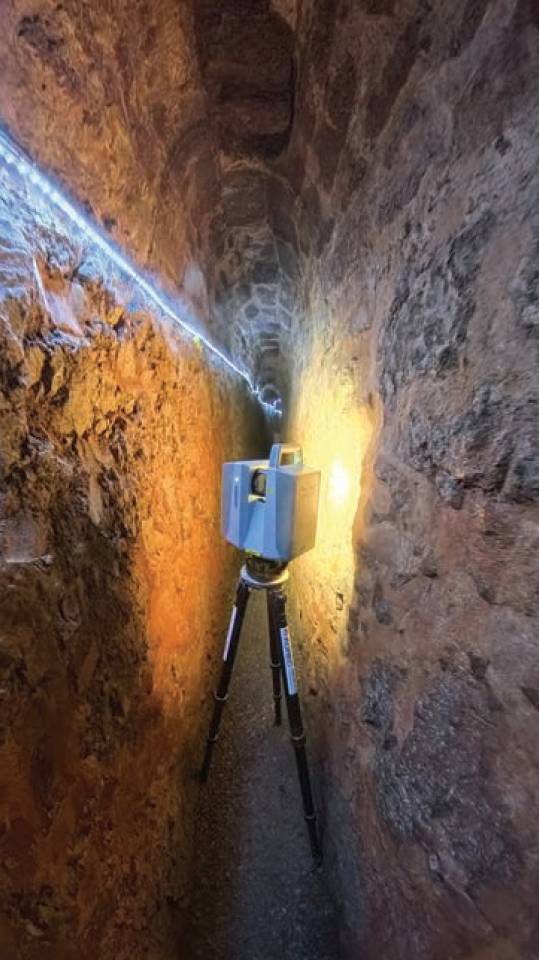

The Trimble X12 3D laser scanner was able to capture the di›erent types of construction materials used in the tunnels.

Above the ground, Benchmark’s Trimble R12i was used to establish position and also the longest baseline with which to tie the site together.

The team then switched to a traverse kit with a Trimble S9 0.5ins angular accuracy total station to create a really tight control network which would minimise the Drift of the laser scanner in the tunnels.

Extra attention was therefore paid to the areas where they could connect the topographic survey with the tunnel survey at four separate sites.

These sites – two tunnel exits, a manhole cover and access via a shopping centre – were scanned using a Trimble X7 3D laser scanner.

At the manhole site, the X7 was used on an inverted tripod to link the above and below ground surveys. All the topographical work was completed in less than three days.

Three challenges presented themselves; overcoming Drift, tunnel width and low light. Having carefully assessed the tunnels, Benchmark felt the only way to tackle a linear project of this complexity was through the creation of a 3D laser scan.

However, it was already aware of a number of site challenges that would rule out using a SLAM system and even prove exceptionally demanding for most 3D laser scanners.

Benchmark therefore opted for the Trimble X12 (supplied by KOREC), that ticked four vital requirements for this project:

- Crisp, clean data delivered with high accuracy and precision (0.30 mm range noise @10m).

- Compact form factor and low weight for easy manoeuvrability within the tunnels.

- Minimum measurement of 300mm for scanning successfully in the narrowest areas.

- Built-in LED spotlights for illuminating the passageways.

The X12’s built-in LED spotlights brought the dark spaces to life with rich, accurate colour.

Drift was the primary concern for the Benchmark team, with the tight above-ground traverse leaving minimal tolerance for error.

To accurately position the tunnel in relation to the surface topography, a precise and stable spatial connection between the surface control network and the tunnel survey was essential.

The control established above ground with the Trimble S9 provided the necessary accuracy to mitigate drift and ensure the reliable alignment of tunnel data, which would be of a high quality courtesy of the X12’s precision.

Throughout the 390m network of tunnels, width ranged between 930mm and 430mm, sometimes with 800mm clearance, making use of a tripod impossible.

The X12 has a minimum measurement of just 300mm and was therefore used on a trig plate – as well as capturing every detail, it was even able to record the screws on the corners of the plate.

Although the Benchmark team could have taken lighting into the tunnel, this was not necessary thanks to illumination from the X12’s four LED spotlights for shadow-free image capture, bringing the dark spaces to life.

Over a two-day period, 131 scans were undertaken, capturing the entire tunnel network including manholes and doorways along with key architectural detail.

This fitted with the 243 scans connecting the modern structures above.

An excerpt from the video produced using the combined scan data, displaying Exeter both above and below ground.

Back at the office, Trimble RealWorks was used to process the scan data. For James and Anthony, the challenge was finding a way to manage a high number of linear scans. A traditional cloud-to-cloud approach was unworkable because the scans were so close together that accumulated error would become a problem. Instead, the data was divided into manageable sections (e.g. 1–5, 5–10 ) and this simplified method was used to define the structure’s shape. These sections could then be infilled and refined to minimise errors between them.

Thanks to careful planning, this complex project was relatively straightforward to complete due to the integration of the various Trimble hardware and software systems used. These included the R12i GNSS, the S9 total station with onboard Access software, the X7 and X12 3D laser scanners with Perspective software, RealWorks for scan data processing and Trimble Business Center for survey data processing.

The project was an overwhelming success, creating something that far exceeds what was already in existence and hopefully creating a bit of history with an amazing dataset. Having successfully captured so much high-quality 3D data, a video of the tunnel network was created. Joshua Rogers produced a fantastic visualisation (available on YouTube) of exactly how it was envisioned the network would look at the beginning of the project. It’s also been great to see the client appreciating how much potential this survey has for both present and future plans for the tunnels.