THE DAWN OF DIGITAL TRANSFORMATION AND AUTOMATION:

REVOLUTIONISING THE FUTURE OF CONSTRUCTION

Despite a historically cautious approach to technology adoption, the sector is now rapidly advancing toward digital transformation, automation and AI, fundamentally altering traditional construction methods and practices. The evolution in construction is indeed reshaping the industry’s job landscape, sparking concerns about job displacement among workers. Automation can reduce the demand for certain manual tasks, creating uncertainty for those whose roles are at risk of being automated.

The construction sector is a key component of the UK economy, contributing approximately 6% to the national gross domestic product (GDP), equivalent to around £119bn annually, according to the Office for National Statistics (ONS) in 2024. This shift towards digitisation and automation presents an essential opportunity to address enduring industry challenges, including cost overruns, labour shortages, inefficiency, productivity barriers, regulatory requirements and data security concerns.

Following the Chancellor of the Exchequer Rachel Reeves’ Autumn 2024 Budget announcement, which emphasised strengthening the UK’s economic foundations through enhanced digital infrastructure, it is time to examine emerging digital transformation and automation trends. This article aims to analyse and delve into the benefits, government policy-driven initiatives, challenges, uncertainties, unknowns and future outlook with some considerations for an industry undergoing a pivotal evolution as it steps into a new industrial age.

The delayed adoption of new technologies in construction has led to stagnant productivity levels, particularly compared to sectors like manufacturing. Aging infrastructure that fails to meet rising sustainability standards and current environmental regulations has further underscored the urgency for modernisation. This need for improvement is reflected in the government’s Construction 2025 strategy, which sets ambitious goals – a 33% reduction in costs and a 50% reduction in project timelines. In this context, digital transformation and automation have become essential rather than optional, necessitating significant investment in the industry.

The government’s recognition and willingness to adopt digital tools could bring substantial benefits to various sectors of the UK construction industry and contribute to UK economic growth. Let’s explore some of the key benefits.

Boosting productivity and efficiency

The UK construction industry has historically faced challenges with cost overruns, low productivity and inefficiency. However, the integration of digital tools such as building information modelling (BIM), drones, robotics and AI-driven project management systems holds substantial potential to streamline processes, reduce errors and shorten project timelines. Through these technologies, the government aims to make construction projects more efficient, cost-effective and better organised.

Addressing labour shortages

The ongoing skilled labour shortage, exacerbated by Brexit and an ageing workforce, highlights the need for digital tools. These technologies can help bridge workforce gaps by performing repetitive or hazardous tasks, allowing human workers to focus on higher-skilled roles. This approach supports sustained productivity, helping prevent project delays and reduce costs amid workforce constraints.

Improving safety and reducing risks

The inherent risks in construction mean automation technologies, such as robotics, autonomous equipment and drones, play a vital role in enhancing site safety. For instance, drones can conduct aerial surveys and site inspections, gathering essential data without exposing human operators to hazardous conditions. In my experience working on the Old Oak Common HS2 project, the use of ‘DroneDeploy’ has been invaluable in delivering safety and efficiency benefits.

Reducing environmental impact

The UK Government has set ambitious climate targets, including achieving net-zero emissions by 2050. Digital tools support these goals in construction by minimising waste, optimising material usage and reducing energy consumption. Integrating AI technologies into BIM enables precise planning through advanced data analysis, helping to prevent material over-ordering and reduce on-site waste, enhancing project sustainability.

Enhancing transparency and accountability

By embracing these technologies, the UK construction sector could become a leader in innovation, opening opportunities for exports and attracting foreign investment.

Digital tools allow construction projects to be monitored in real time, providing live data on progress, costs and regulatory adherence. This transparency improves accountability among stakeholders, reducing delays, cost overruns and the risk of corruption especially important for public sector projects where taxpayer funds are at stake.

Increasing quality, longevity of infrastructure and enhance project outcomes

Digital technologies such as 3D scanning and sensors enhance quality control in construction, ensuring that structures are built to high standards and designed for longevity. Specialised sensors embedded within buildings can monitor structural health over time, supporting proactive maintenance and extending the life of public infrastructure. Additionally, the use of self-healing construction materials such as Sensicrete, a self-healing concrete which was developed by Sensicon (a partner of Basilisk), presents a valuable advancement, offering insights into infrastructure lifespan and durability performance.

Driving economic growth and global competitiveness

The UK’s Construction 2025 strategy views digital transformation as essential for modernising the construction industry and maintaining its global competitiveness. By embracing these technologies, the UK construction sector could become a leader in innovation, opening opportunities for exports and attracting foreign investment, which is particularly important in the post-Brexit landscape.

Supporting remote and hybrid work models

The COVID-19 pandemic accelerated digital tool adoption across industries, including construction. Cloud-based platforms, digital collaboration tools and remote monitoring technologies now enable stakeholders to collaborate and oversee sites from various locations. This flexibility fosters a more agile, efficient approach to project management and improves carbon footprint.

Artificial intelligence (AI) and machine learning

AI and machine learning are increasingly used to enhance project planning, resource allocation and risk management. In the UK, AI-driven tools like BIM analyse data from past projects to generate insights into timelines, budget risks and potential challenges, enabling more accurate forecasting and proactive issue resolution. Through these advancements, the UK Government aims to cultivate a modern, productive and sustainable construction industry aligned with broader economic, social and environmental objectives.

This initiative underscores the government’s commitment to adopting digital transformation and automation in the industry, emphasising the urgent need for development.

In the Autumn 2024 Budget, Chancellor of the Exchequer Rachel Reeves emphasised the need to strengthen the foundations of the UK economy by enhancing digital infrastructure in underserved areas and supporting growth in the digital and technology sectors. The government plans to invest over £500m in Project Gigabit and the Shared Rural Network in 2025.

As part of this budget announcement, the government will assign chief scientific adviser, Professor Dame Angela McLean and national technology adviser, Dr Dave Smith to lead a review examining barriers to the adoption of transformative technologies that could enhance innovation and productivity, particularly in the growth sectors identified in the Industrial Strategy green paper. The recommendations from this review will directly inform the development of the industrial strategy and sector plans, which will be released alongside phase two of the spending review.

Furthermore, the King’s Speech on 17 July 2024 highlighted the Planning and Infrastructure Bill, aimed at accelerating the delivery of high-quality infrastructure and encouraging investment in new technologies. This initiative underscores the government’s commitment to adopting digital transformation and automation in the industry, emphasising the urgent need for development.

The UK Government is actively promoting digitisation and automation within the construction sector to enhance productivity, sustainability and efficiency. Through various initiatives, funding programmes and policy frameworks, the government aims to modernise the construction industry, reduce carbon emissions and address labour shortages. Let’s examine some key aspects of what this support include.

Construction Sector Deal (part of the UK Industrial Strategy)

Launched as part of the UK’s broader Industrial Strategy, the Construction Sector Deal establishes a framework for transforming the industry, prioritising digitisation, offsite manufacturing and sustainability. The deal allocates over £420m in combined government and industry funding to foster innovation and skills development. It focuses on digital techniques with the adoption of building information modelling (BIM) and other digital tools to enhance construction processes, offsite manufacturing for modular construction methods that improve productivity and minimise waste and whole-life asset performance that ensures buildings and infrastructure are sustainable and efficient throughout their entire lifespan.

Building information modelling (BIM) mandate

In 2016, the UK government mandated the use of BIM Level 2 for all centrally procured public projects, requiring the implementation of digital models and collaborative working processes. The adoption of BIM is a crucial driver for digitisation, facilitating enhanced project management, planning and resource allocation through virtual project simulations. The BIM mandate is integral to the government’s efforts to improve transparency, reduce errors and ultimately lower project costs and timelines.

Transforming construction challenge (TCC)

The transforming construction challenge is a £170m government-led initiative under the industrial strategy challenge fund (ISCF), focused on accelerating innovation in the construction sector. It supports projects that develop new technologies, processes and business models that promote modern methods of construction (MMC), such as robotics, AI and 3D printing. The challenge aims to build ‘smarter, safer, greener’ buildings and infrastructure, with a goal of reducing project delivery time by 50% and carbon emissions by 50% by 2025.

Construction Innovation Hub

Funded by the ISCF, the construction innovation hub (CIH) collaborates with industry, institutions, academia and government to drive technological advancements and standardisation. The CIH promotes platforms like the platform design for manufacture and assembly (P-DfMA ), which advocates for standardised, prefabricated components that can be manufactured offsite and assembled on site. This helps to improve project timeline, reduce on-site construction complexities and associated risk and promotes innovation through value engineering. It also works on the value toolkit, a framework for assessing project value across environmental, social and economic factors, encouraging a holistic approach to construction beyond initial costs.

Digital Built Britain

Launched in 2015, the Digital Built Britain (DBB) programme extends the principles of BIM to a wider framework known as BIM Level 3, focusing on the integration of data across the built environment. DBB aims to create a national digital twin, a digital replica of the country’s built assets, providing insights for better management and maintenance of infrastructure. The programme emphasises data sharing and interoperability, aiming to create a digital ecosystem that allows seamless information exchange between government, industry and stakeholders.

Construction Playbook

Published in 2020, the Construction Playbook provides guidelines for government departments on procuring and managing public sector construction projects. It encourages digitisation and the use of digital twins, data standards and digital project management tools to improve decision-making, reduce risk and enhance efficiency, focusing on outcomes rather than lowest-cost delivery.

Support for skills and training in digital construction

The UK Government collaborates with educational institutions and industry bodies to address the digital skills gap in construction. Initiatives like the construction skills fund and technical level qualifications offer training programmes focused on digital skills, including BIM, project management software and automation technologies. The government also supports apprenticeships and partnerships with technology companies to increase expertise in areas like robotics, data analytics and machine learning.

Sustainable construction goals and initiatives

Automation and digital technologies are integral to the government’s net zero 2050 target for the construction sector, aiming to significantly reduce carbon emissions. The policies promote green building design, efficient material use and asset lifecycle tracking and encourage the adoption of digital solutions to manage carbon output and minimise waste. The energy performance of buildings directive (EPBD), though originating from EU law, continues to shape UK regulations, promoting energy efficiency, digital monitoring of building performance and energy performance tracking across a building’s lifecycle. It mandates the use of energy performance certificates (EPCs) and display energy certificates (DECs) to provide transparency on energy efficiency and facilitate ongoing performance monitoring. The emphasis is on employing digital construction methods to reduce environmental impact and optimise resource use across a building’s entire lifecycle.

Tax incentives and funding programmes

The research and development (R&D) tax credits programme allows companies investing in digital technologies and automation within the construction sector to claim tax relief. The government has also introduced various funding initiatives, including the Future of Mobility Urban Strategy, to support technology adoption in urban infrastructure projects, advancing the development of smart cities and intelligent transportation systems.

Partnerships with industry bodies and collaboration

The construction industry in the UK, like many others globally, faces unique challenges in adopting digitisation and automation.

The government collaborates with industry groups like the Construction Leadership Council (CLC), Centre for Digital Built Britain (CDBB), and Innovate UK to align policy objectives with industry requirements. These partnerships help streamline adoption, standardise processes, and establish benchmarks for innovation within the sector, creating an ecosystem that supports continuous improvement in the construction industry.

The construction industry in the UK, like many others globally, faces unique challenges in adopting digitisation and automation. While digital tools and automated processes offer potential improvements in efficiency, quality and safety, several key obstacles stand in the way. Let’s take a look at some of the primary challenges.

High costs of implementation

Digital tools require significant upfront investment and for many construction companies, especially SMEs (small and medium-sized enterprises), the high cost can be a deterrent. The ongoing maintenance cost for digital infrastructure and upgrading software systems can be expensive and is often not feasible for companies operating on tight margins.

Workforce skills shortage

The continuous shortage of workers with expertise in both construction and digital skills, particularly in operating and maintaining digital tools and automated machinery can be challenging for the industry. Many workers are also accustomed to traditional methods and may be resistant to adopting new technologies.

This resistance can hinder widespread adoption and limit the effectiveness of digital tools. Training the workforce to effectively use new technologies can be costly and time-consuming and for smaller companies, this can be particularly challenging.

Fragmented industry structure

The construction industry in the UK is highly fragmented coupled with the lack of standardisation, with many small, specialised contractors working on individual parts of a project. This makes it difficult to implement standardised digital processes across projects. Digitisation requires collaboration across various stakeholders, including architects, engineers, contractors and suppliers who use different software systems, making integration a challenge. Incompatible systems can hinder the flow of data, impacting efficiency and interface construction activities.

Regulatory and compliance issues

The collection of data from sites, workers and equipment raises issues related to data privacy, particularly with regulations such as the General Data Protection Regulation (GDPR). Companies need to ensure that they manage data securely, which can add complexity. The slow adaptation of regulation and the rapid pace of technological change means that regulations often lag behind, creating uncertainty for companies investing in new digital solutions. This can slow adoption, as businesses wait for clearer regulatory guidelines for integration.

Cybersecurity risks

The advancement of digital platforms means companies become more vulnerable to cyber threats. Cybersecurity risks are particularly high for companies storing sensitive data or relying on automated systems for critical tasks. The lack of expertise needed to safely secure their systems makes them vulnerable to data breaches and ransomware attacks. The need for robust cybersecurity measures adds to the cost and complexity of digitisation, which could be challenging for SMEs.

Interoperability and integration issues

Different companies and stakeholders often use incompatible software, making it challenging to integrate digital solutions seamlessly across the entire construction process. This can limit the benefits of automation and hinder communication between stakeholders. Automation efficiency requires easy access to shared data across platforms. Without integrated systems, data remains siloed, reducing the effectiveness of digital workflows and compatibility.

Complexity of project environments

Different companies and stakeholders often use incompatible software, making it challenging to integrate digital solutions seamlessly across the entire construction process.

Construction sites are usually dynamic and often subject to changing conditions such as weather, unforeseen physical and ground conditions and other unpredictable factors. This makes implementing and maintaining automated systems, such as robotics, particularly challenging. The uniqueness of construction projects often requires custom digital solutions and the lack of a one-size-fits-all solution increases costs and complicates implementation efforts.

Environmental and sustainability concerns

Regulatory compliance and societal pressure for sustainable practices means that digital tools must also align with green building initiatives, such as reducing carbon emissions and minimising waste. Implementing technologies that meet both digitisation and sustainability standards can be challenging. Some digital tools, especially data centers and cloud services, have significant energy requirements, which can be at odds with sustainability goals in construction projects focused on reducing carbon footprints.

Return on investment (ROI) uncertainty

The return on investment in digital tools, especially for SMEs is not always clear, particularly if the benefits are long-term. This uncertainty can make companies reluctant to invest in technology without a clear, immediate payoff. Competitive tenders and tight profit margins can be challenging to incorporate the cost of digital tools into bids. Quantifying the benefits such as improved efficiency or reduced error rates, can be challenging, making it harder for companies to justify these investments to stakeholders.

Conservative construction industry culture

The slow adoption of new technologies compared to other industry sectors, partly due to its high focus on risk, health and safety, welfare and quality management can create a cultural barrier to the adoption of digitisation and automation. Digital transformation requires leaders who understand both construction and digital technology to contribute in policy-making decisions and initiatives to foster a strong industry culture where the benefits are clearly defined. The shortage of such leaders in the construction industry contributes to the slow pace of change.

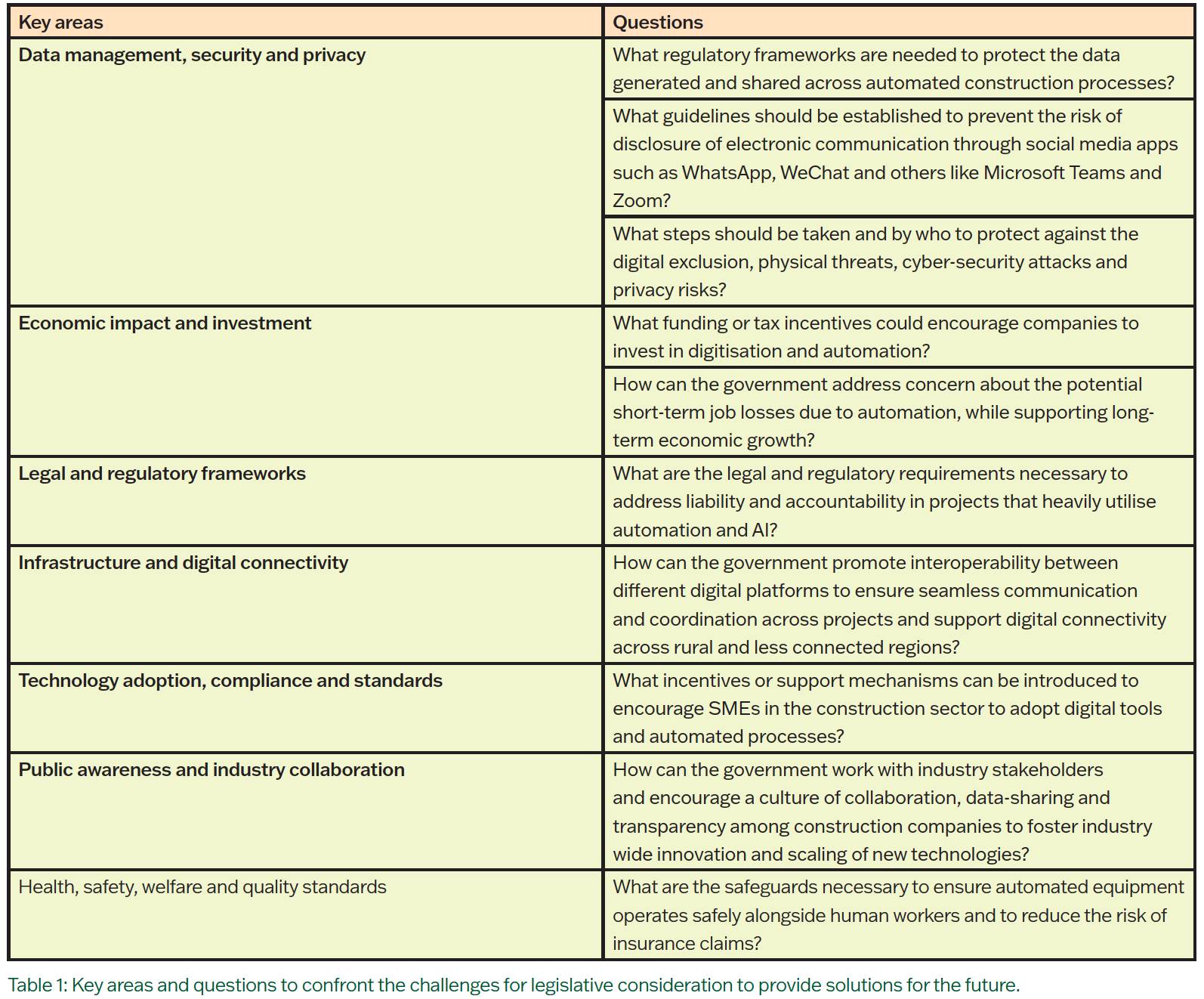

To confront the challenges of digitisation and automation in the UK construction industry, the UK Government could consider a series of targeted questions that address the practical, regulatory, and economic aspects of this transformation. Table 1 shows some of the key areas and corresponding questions for consideration. By addressing the questions in Table 1, parliament can guide the construction industry toward a future that balances productivity and growth with social, economic and environmental responsibilities.

To overcome these challenges, the industry may benefit from a combination of government incentives, industry collaboration on standardisation, investment in workforce training, and partnerships with technology firms to develop affordable, construction-specific digital tools. Additionally, fostering a culture of innovation and adaptability within construction firms could accelerate the adoption of these transformative technologies. The UK construction industry faces several hurdles in implementing digitisation and automation, but there are multiple solutions to help overcome these challenges. Here are some key approaches.

Upskilling and reskilling the workforce

Establish industry-wide training programmes focused on digital tools, building information modelling (BIM), robotics and data analytics to address the lack of digital and technical skills. Collaboration between the government, industry bodies and educational institutions can help create apprenticeships and certification programmes to upskill workers. An article by Dan Milmo, featured in The Guardian on 8 November 2024, highlighted a report from Tony Blair’s think tank titled ‘The impact of AI on the labour market’, which suggests AI could displace between 60,000 and 275,000 jobs annually over the next decade. The report stated that administrative jobs would be most affected, along with sectors like sales, customer services, banking and finance, as AI can increase efficiency by significantly saving time and costs when deployed1.

As new digital tools and systems are integrated, there is a growing demand for skilled workers who can oversee, manage and maintain these technologies. Upskilling initiatives allow workers to transition into roles involving operating AI-driven machinery, analysing data and managing digital platforms. Embracing this shift and investing in training programmes can help the construction workforce adapt, ensuring they are not only protected from job losses but also equipped to thrive in an evolving industry.

Improving interoperability of systems

Construction projects frequently involve diverse stakeholders and tools, leading to data silos and challenges in data sharing. Developing standards and frameworks to enable interoperability across different software and systems is essential. This could include adopting open data standards that facilitate seamless data exchange between platforms used by various project teams. A typical example is the use of the asset lifecycle information management (ALIM) system on the HS2 OOC project. Despite the initial implementation challenges, it has proven invaluable for enabling data sharing with a high level of asset information accuracy across project teams.

Tackling high implementation costs

Providing financial incentives such as grants, subsidies or tax breaks for small and medium-sized enterprises (SMEs) investing in digital transformation could alleviate this challenge. Additionally, government-led funding programmes or public-private partnerships could play a crucial role in subsidising technology adoption.

Streamlining regulatory and compliance standards

Construction regulations are often complex and can lag behind technological advancements, creating uncertainties around compliance. Collaborating with regulatory bodies to adapt existing regulations for digital tools and automation can help address this gap. Streamlined and updated regulations would facilitate faster adoption of new technologies while maintaining essential safety and quality standards.

Enhancing data security and privacy measures

The rise in digitisation introduces risks of data breaches and cyber-attacks, potentially resulting in financial and reputational harm. To mitigate these risks, implementing robust cybersecurity protocols and providing training on best practices is essential. Partnering with cybersecurity experts can further help construction companies establish data governance frameworks and security measures to safeguard sensitive information and protect their assets.

Promoting industry-wide collaboration and knowledge sharing

Fragmentation within the construction industry limits the sharing of best practices and technology insights, hindering progress. Encouraging knowledge-sharing platforms, such as industry forums, workshops, conferences, and webinars where companies can share insights, case studies, lessons learned and ideas for continuous improvement, is essential. Initiatives led by professional associations like the Construction Industry Training Board (CITB) can promote collaboration across the sector.

Integrating digital twin and BIM technologies

The increased pressure to meet sustainability goals complicates digital transformation efforts.

The adoption of BIM and digital twin technologies remains limited, with many companies still dependent on outdated methods. Mandating the use of BIM and digital twins in large public projects, alongside providing targeted training, could accelerate industry-wide adoption. Government leadership and support in implementing these technologies would set a benchmark for private companies to emulate.

Leveraging public-private partnerships

Encourage public-private partnerships to stimulate innovation within the construction sector. For example, these collaborations can focus on pilot projects that showcase the effectiveness of automated systems, such as robotics for construction tasks or drones for site inspections. Such partnerships enable both public and private entities to share the associated risks and rewards of adopting innovative technologies.

Encouraging sustainability and innovation through digital tools

The increased pressure to meet sustainability goals complicates digital transformation efforts. Leverage digital tools to support sustainability efforts, such as reducing waste and optimising energy usage on construction sites.

Digital twins, for example, can simulate and optimise energy use in buildings, while AI-driven systems can reduce material waste and enhance resource efficiency.

Increasing government support and strategic initiatives

The lack of cohesive policy frameworks and national initiatives can slow down the digital transformation process. The UK Government can play a pivotal role by setting clear, actionable policies that support digitisation in construction. For instance, establishing a digital construction task force or creating a national strategy for construction innovation could unify and guide the sector’s efforts toward modernisation. By addressing these challenges through a combination of strategic planning, financial support and workforce development, the UK construction industry can build a strong foundation for digitisation and automation, ensuring greater productivity, efficiency and competitiveness in the years to come.

Key UK policymakers are pushing for digitisation and automation in the construction industry to enhance efficiency, cut costs and meet sustainability targets. Anne-Marie Trevelyan, former secretary of state for business and trade, supported the Construction Playbook, endorsing digital tools like BIM to improve project management. Andrew Stephenson, a former Department for Transport minister, advanced digital integration in major projects such as HS2, leveraging digital twins and predictive analytics.

The Infrastructure and Projects Authority (IPA) leads the Transforming Infrastructure Performance (TIP) strategy, promoting digital tools across public projects, aided by bodies like the Centre for Digital Built Britain (CDBB). This digital shift aligns with government initiatives to modernise construction, supported by incentives and regulations. Jonathan Reynolds, the new Secretary of State for Business and Trade, is expected to continue this push amid challenges like those seen with HS2.

Research by the Parliamentary Office of Science and Technology and Amazon Web Services estimates that digitalisation could add £413bn equivalent to 19% of the UK economy by 2030. Such growth hinges on improved digital skills, connectivity and clear regulatory frameworks to facilitate technology adoption and position the UK as a global leader in the new industrial era.

The government’s policy and commitment to modernising infrastructure through digitisation and automation will be crucial to overcoming obstacles for long-term economic growth and harnessing the benefits of an evolving industrial landscape. The challenges and uncertainties remain with the advancement of digital tools, AI, blockchain technology and quantum computing technology, which will be fundamental in the technological shift.

As the construction industry advances toward greater digitisation and automation, there is a greater need for continuous enquiry to ensure that technological progress enhances human roles rather than diminishes them, addressing inherent fears of the unknown while preserving the dignity, safety and purpose of the workforce.

With the dawn of digital transformation and automation, we are entering a new industrial age whose evolution will be closely and thoughtfully observed.

---