The role of verification in the construction industry

Adam Box, Vertical Construction Business Development Manager, Topcon Positioning Systems, talks to Danielle Kenneally

THE costs associated with the construction design and assembly process are high and rising. This is driving Topcon Positioning Systems forward as it looks to improve the efficiency of on-site crews. The future is now. The aim is to provide scalable solutions underpinned with smarter building infrastructure that is customer driven and more efficient. However, with many contractors often opting for familiar machinery, Adam Box, Topcon’s vertical construction business development manager across Europe, the Middle East and Africa, often finds informing the industry about new technologies that are available challenging. He spoke to Civil Engineering Surveyor about the issues facing the construction industry and what the future could hold to benefit it.

How is hardware and software used within the construction industry?

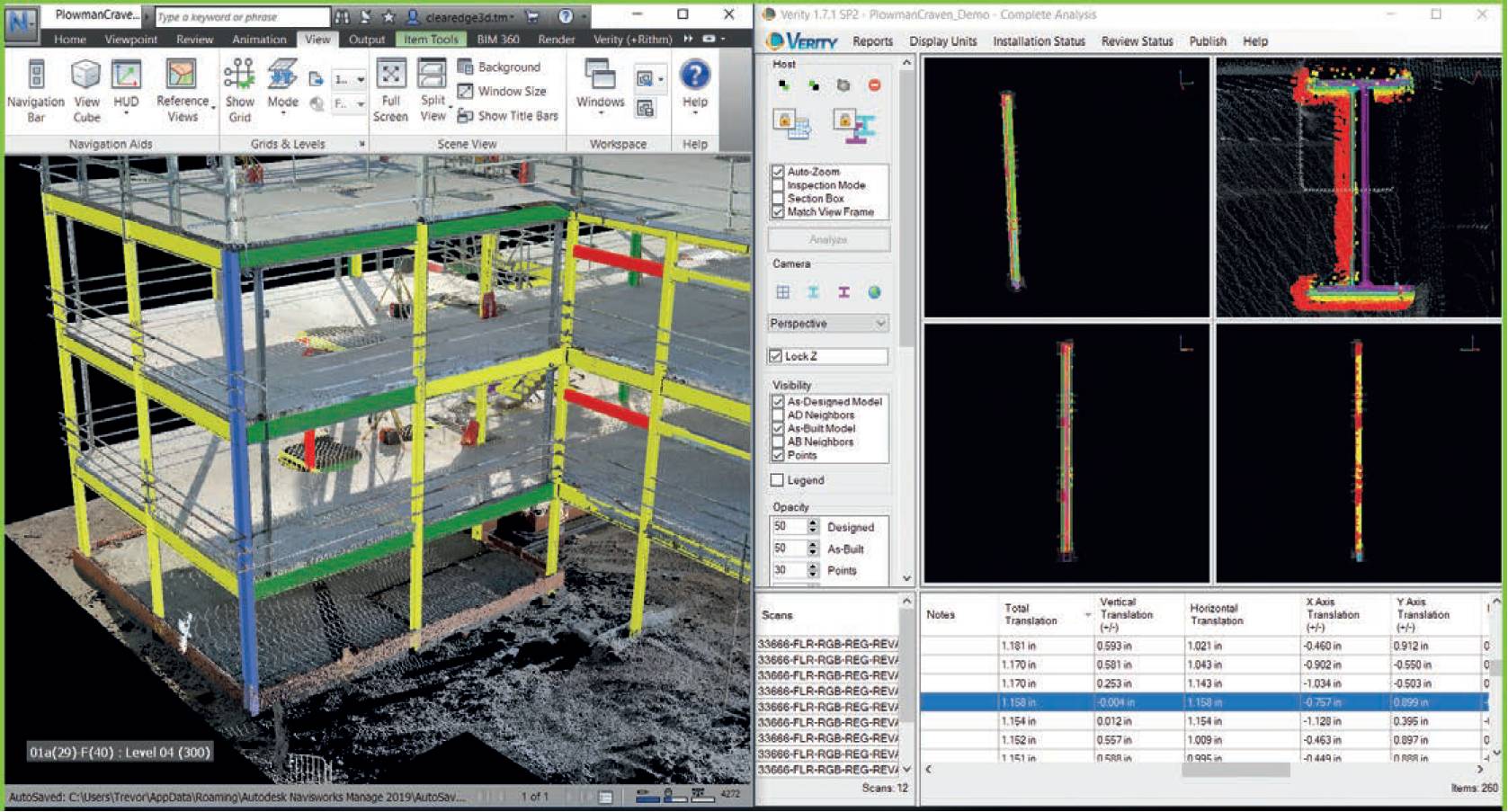

Software underpins everything. While hardware is the instrument, software does the really impressive stuff in my opinion. This compares the point cloud and the model and highlights inaccuracies or mistakes between reality and digital plans. Tools like construction verification software, such as ClearEdge 3D Verity, allow on-site teams to pick up mistakes almost instantly. This means they can be rectified straight away, avoiding costly problems and rework further down the line.

What challenges have there been?

One of the big challenges that you’ll see is the deviation between plans and reality; where something should be and where it actually ended up. The rise of laser scanning has given us the ability to capture a current environment at a point in time. What we’re doing now is trying to improve the ability by which you can align the model with the laser scan in a way that is completely accurate. There are a lot of different aspects to the construction process and there’s no doubt that construction verification presents a real opportunity to help the industry to work more accurately and effectively.

What are you trying to do to help?

One of the things that we are trying to do is to resolve the issue around somebody creating a design which won’t actually be feasible to deliver in the real world. Everyone can create perfectly detailed 3D models but the big problem is that as soon as you go on to a physical job site, everything changes. Real-time data can be provided so teams can communicate, share information, and collaborate even when they are spread across different sites. For us, it’s critical to try and offer a more complete answer to a problem. We’re sharing point clouds, allowing them to be pushed out to different participants and integrated into existing workflows. It’s important to keep innovating and coming up with better ideas. Going along with the status quo is never a good strategy.

Using ClearEdge 3D Verity.

How does your role come into that?

We all know how much pressure construction is under to do things better. There are huge pressures to reduce waste and carbon emissions. Technology is going to be one of those main threads that helps with this. Within Topcon, I try my best to articulate how technologies can help deliver projects more efficiently, sustainably and effectively than ever before.

We operate across Europe, the Middle East and Africa, so before the pandemic I was travelling quite a bit, seeing lots of different people and supporting our colleagues. The pandemic flattened that, so my role became online-orientated as it did for most people. It’s now beginning to pick up again so I’m able to get out and about, into face-to-face meetings, shows and events which have proven to be so critical.

We learned to cope without them for a time, but we are able to have different conversations in-person that just don’t happen in an online environment.

Using the GTL - 1200.

Have there been any major advancements to help with construction verification?

When it comes to construction verification software, there are advanced solutions available that can process data really quickly. Everybody knows that a great way of capturing data on the site is to scan it, but it often requires an external company, which is reliant on external hardware.

On the hardware side we looked at the way things were done and re-engineered it. We created a hybrid device by combining a robotic total station, which is commonly used within construction, with a laser scanner – the GTL-1200.

This is part of a critical workflow that allows the instrument to be driven directly from a tablet – it helps somebody on-site capture the data and process it quickly. We’re trying to remove the age-old problem of scanning being separate to everything else.

Are there other challenges that come up against this?

We’re trying to remove the age-old problem of scanning being separate to everything else.

There are all sorts of pressures, one of the main ones being the skills and recruitment crisis.

We’ve got an ageing population with many contractors moving out of the sector and not being replaced.

Technology can help with this to an extent – as artificial intelligence becomes smarter, it can deliver many answers, but automated machines will still require assistance and a level of onsite monitoring; human intervention will always be a key part of the industry.

Are there pressures within the industry itself?

There're all sorts of pressures – we’re a problem, we’re an awful problem because on a construction site, we are desperately trying to think of ways of killing and injuring ourselves. We’ve got to solve this.

There’s also technology – I’m a great advocate of it. Technology is increasingly being used, whether people want it or not. It’s not the construction industry’s choice, but it can’t be ignored and it’s not going to go away.

Technology can deliver many answers when it comes to building design, it might not look pretty, and maybe there’ll be a place for humans to make things look more acceptable, but the core requirements of how a construction project is done, will be replaced by technology. Automated machines will still require assistance, and a level of onsite monitoring will be needed as artificial intelligence becomes more intelligent, but for now, there’s still teams needed to keep a close eye on the accuracy of projects and the accuracy of machines.

Is the cost of technology an issue?

Having a healthy level of interest and curiosity about technology and new developments is key, as is finding creative ways to utilise them to grow your business. Otherwise, we’re just going to become an old profession.

Not at all, it’s balanced against the extra efficiency and productivity it gives. People don’t know what they don’t know. When they move into this space, they suddenly realise how much time can be saved through automation.

What about the future then?

We are looking at moving towards an assisted environment. At the moment, there are cool things going on around self-guided machine control, with machines grading automatically. The driver maintains the level of the blade and the system controls the grade. This helps to make the operator much more efficient so that they get it right. There’s no overcut, you don’t have errors, you don’t have omissions.

It’s not about replacing people with robots, but how to make people more efficient; how you help them move more quickly and deliver the project on time.

What are your pointers for CICES members?

Having a healthy level of interest and curiosity about technology and new developments is key, as is finding creative ways to utilise them to grow your business. Otherwise, we’re just going to become an old profession. The industry needs to be flexible and grapple with this ever-increasing pace of change.

I’m truly passionate about what we’re doing at Topcon, and I can see the results we’re delivering for businesses. Investing in digitalisation delivers immediate benefits for construction businesses of any size, and with the right solutions, they will also be prepared for further changes in future.

Adam Box, Vertical Construction Business Development Manager,

Topcon Positioning Systems