Connecting Indonesia to the World

Steve Cockerell, Bentley Systems

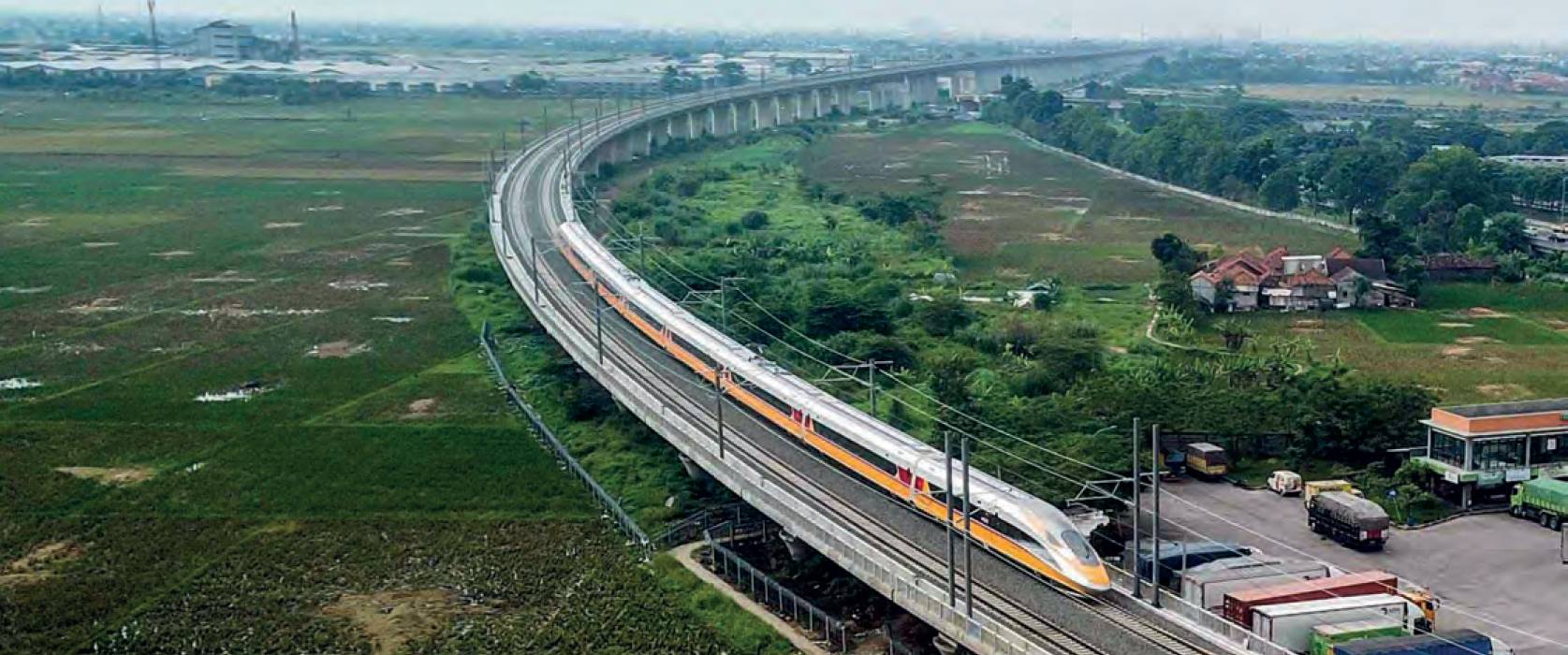

LOCATED in Southeast Asia and made up of over 17,000 islands, Indonesia has become a popular tourist destination.

However, to compete with other travel locations, the government realised that it needed to provide reliable, efficient, safe, and comfortable public transportation. Therefore, it planned to create an integrated high-speed rail between the capital of Jakarta and the shopping district of Bandung.

The $7.8bn USD project stretches 143 kilometres in length and features 55 subgrade sections, 13 tunnels, 46 bridges, and four integrated central stations. When complete, it will reduce congestion and cut the journey time between the two cities from three to 10 hours by automobile, depending on traffic, to just 36 minutes by rail.

PT Wijaya Karya (WIKA) was hired as the lead contractor on this vast, complex project. In addition to the sheer scale of the rail line, the team had to deal with geological challenges.

The design includes one tunnel requiring construction under a busy toll road, with many buildings around it, which significantly increased project construction risks.

The team also had to ensure that there were multiple connection points so that they could later integrate it with a separate project.

In addition, creating the tunnel would be difficult because of the extreme clay shale soil, which can lead to slope and tunnel heading instability.

Improving communication to meet important milestones

In addition to the geological challenges, the pandemic also impacted the project. Lockdowns and restrictions delayed material transportation, and 1,500 workers had to be quarantined. Another challenge was that in 2022, the government asked that construction be accelerated by 2% per month to meet the 2022 G20 Bali summit, which took place in mid-November. The project needed to be completed by the end of 2022 and fully operational by mid-2023.

The $7.8bn USD project stretches 143 kilometres in length and features 55 subgrade sections, 13 tunnels, 46 bridges, and four integrated central stations.In the past, WIKA used CAD and 2D aerial photographs to produce detailed engineering design plans, as well as conventional survey methods to create 2D terrain and railway plans.

However, these methods caused project delays, increased costs, led to inefficient construction work, and required multiple adjustments that delayed approval.

Therefore, WIKA realised its their traditional methods would not work on this project and sought an integrated BIM and digital twin solution to overcome the significant challenges faced by the team.

Developing a data-centric approach

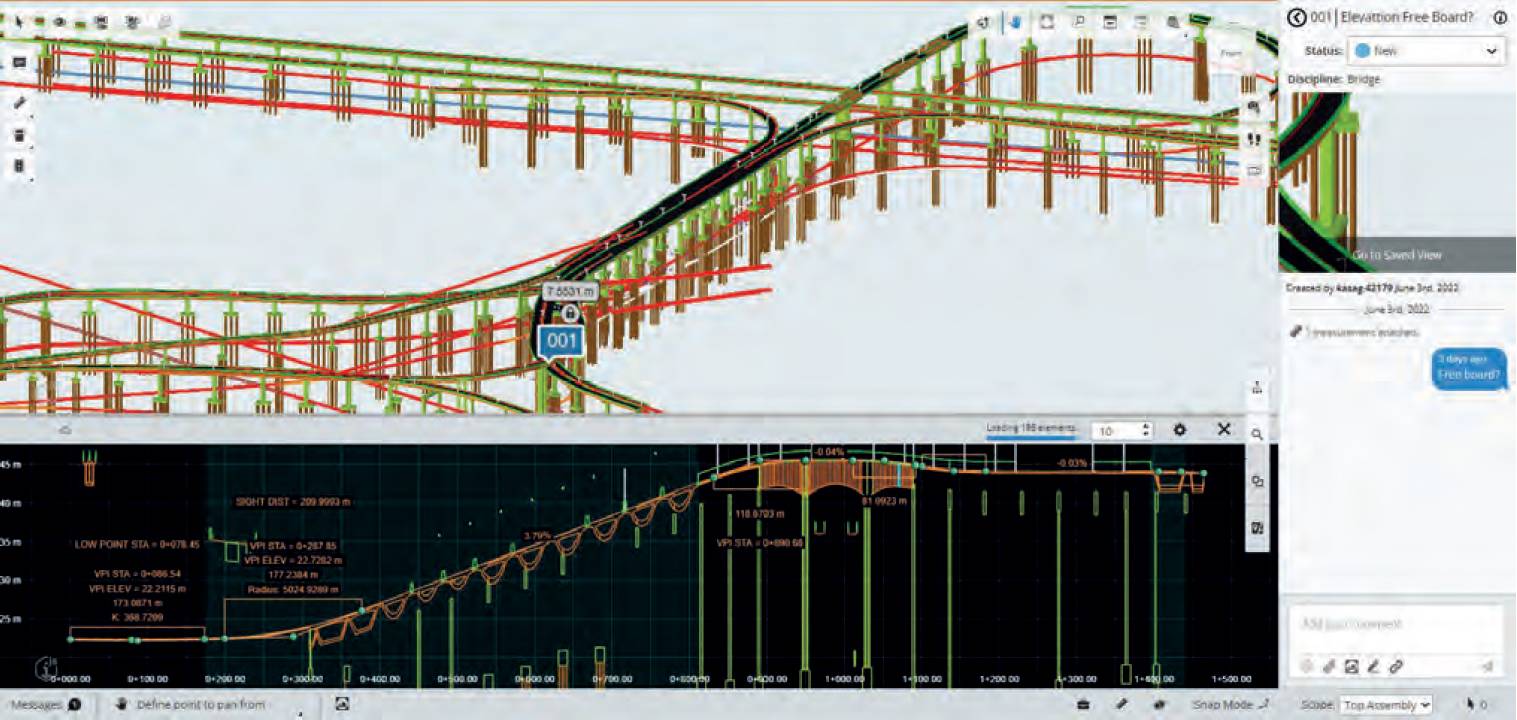

Already familiar with Bentley applications, WIKA chose Bentley’s open civil design and reality modelling capabilities, as well as digital twin technology, to develop a connected digital ecosystem and a single source of truth for project information.

The team began by using ContextCapture to gather drone-captured images, using 135 ground control points to maximise geometric and geospatial precision of reality data. Doing so minimised the curvature and gap of the model. For drone restricted areas, the team used 3D laser scanners.

By using OpenRail, the team modelled 16.8 kilometres of tunnels along the route, reviewing design data and presenting alternative design options to stakeholders. These designs could be easily modified based on feedback, streamlining the decision-making process.

With OpenRoads, WIKA estimated the number of country lane relocations at several crossing points.

They also provided drainage analysis to minimise floods and avoid disturbing traffic and the surrounding areas.

OpenBridge helped the team create bridge models along the proposed route, enabling the detection of 41 clashes and redesign of structures before construction began.

The project will be delivered in time for several important events that will take place in Indonesia, including the ASEAN INDONESIA 2023 and the FIBA Basketball World Cup 2023. The provision of a globally competitive and sustainable high-speed line is a significant milestone of Indonesia becoming a developed country by 2035.Using SYNCHRO with OpenBridge, WIKA simulated construction of a 128-metre bridge, which contained the longest span continuous girder on the project.

By using SYNCHRO, the team was confident that it had chosen the optimal construction method, and that it would not interfere with the four other infrastructure projects running simultaneously.

Additionally, SYNCHRO helped WIKA visualise the sequence of every construction step for every span of the box girder, creating a more efficient workflow and helping to better manage material and resources.

WIKA delivered the combined model using iTwin Design Review, which simplified coordination among multiple disciplines. Stakeholders were better able to understand design intent and the impact of design choices in the digital twin, significantly improving decision-making.

Saving time and cost with digital twins

By streamlining workflows, improving efficiency, and increasing design quality, WIKA saved $185m USD in construction costs and shortened the construction schedule by six months. Bentley’s OpenRail application facilitated contractor involvement and increased productivity and design quality assurance by 40%, compared to conventional methods.

By performing clash detection, the team identified and resolved 108 potential conflicts in the design review stage, which helped avoid costly rework during construction.

With a connected data environment, WIKA expects to save 20% of construction time, reduce labour cost by 10%, and cut meeting frequency by 35%. The digital twin improved accessibility to the design data by 30%, saving a significant amount of time in the first year of implementation.

On schedule to be fully operational in June 2023, WIKA is set to deliver the fastest conventional high-speed railway in the world, with a maximum speed of 400 kilometres per hour. The project will be delivered in time for several important events that will take place in Indonesia, including the ASEAN INDONESIA 2023 and the FIBA Basketball World Cup 2023.

The provision of a globally competitive and sustainable high-speed line is a significant milestone of Indonesia becoming a developed country by 2035. Upon completion, WIKA is planning to replicate the success that it has achieved on the project, applying lessons learned, and leveraging the digital twin as its starting point for the design and construction of the next high-speed railway from Bandung to Surabaya.

Steve Cockerell, Bentley Systems

All images courtesy of PT Wijaya Karya (Persero) Tbk