Heritage

Mapping out history on the Dudley Canal

Above and below ground data collection in a unique and challenging environment

THE Dudley Tunnel is the second longest canal tunnel on the UK canal network, the main tunnel measures over 2.5km long. Construction of the tunnel began over 240 years ago in 1775, and was first opened on 25 June 1791. The tunnel was constructed by Lord Dudley and Ward as a branch canal from the Birmingham Canal to the Tipton Colliery, and a 250-yard tunnel to the limestone mines under Castle Hill.

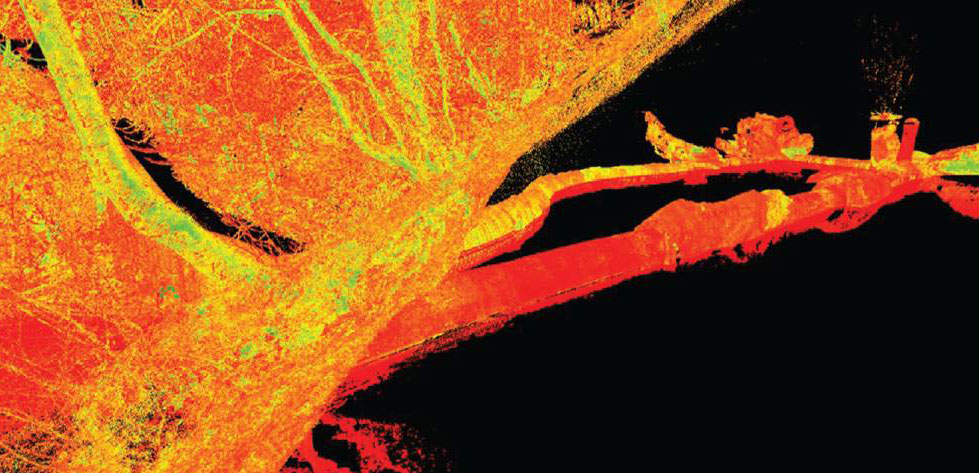

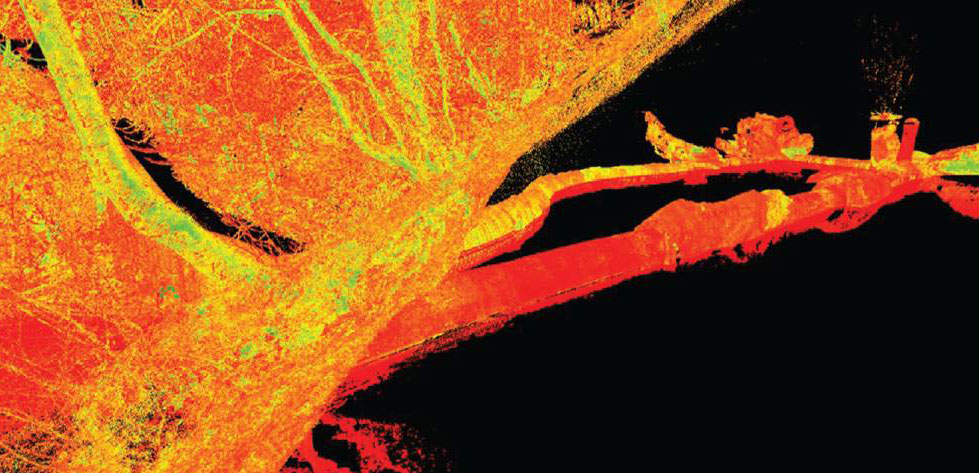

Scan data of the tunnels captured from the basin

The tunnel remained in operation for over 170 years until it was closed in 1962. A collaboration between local volunteers (originally the Dudley Canal Tunnel Preservation Society, later the Dudley Canal and Tunnel Trust (DCTT)), and the local authority, Dudley Borough Council, led to the tunnel being reopened to the public as a tourist attraction in 1973.

DCTT is responsible for the preservation of the canal, tunnels, and the unique underground caverns. Founded in the 1950s, it became a heritage attraction in 1980, providing members of the public with unique tours of the 18th century abandoned mines built within the tunnel and the 19th-century canal infrastructure which served the mines.

In late 2020, DCTT began to explore how new technology could help with the ongoing care and preservation of the system, help it to understand movements, stress points and produce a proactive rather than reactive approach to its work. The goal was to produce engagement and interpretation materials for specialist and general public interest, as well as to raise the profile of the unique environment and produce a complete 360º understanding of the system by viewing and scanning above ground, below ground and underwater and joining the three disparate layers together. This meant a review of the current monitoring and inspection approach and bringing in new technology to adapt it.

The overall aim of the trust was to invest in a range of products and solutions, agreed with Historic England, for the purpose of full system scans and digital modelling. The information captured would be made available on a public platform, with the further objective to apply for further funding to expand the project to include exploration of non-public areas.

Johnson Poole & Bloomer was contracted by the trust to provide a georeferenced point cloud model of the portal building, underground network of tunnels, caverns and woodland topography which could be subsequently processed in a multitude of ways to create the required outputs.

The works were undertaken over a period of 18 days on site, and 10 days of processing to get the required output. Additionally, monitoring was set up using the Leica P40 laser scanner on one of the pillars within Singing Cavern from March to September to allow Arup to create a theoretical finite element (FE) stress test model using the data provided.

A unique challenge

With the underground network being predominantly traversed solely by boat, the project required a unique approach to collect and connect the various environments in order to create a holistic model of the various environments. Additionally, being underground, there are only limited areas that have access to the external topography in order to connect to external control via total station and GNSS.

The survey team mounts the RTC360 to the support beam at the entrance to the second stage of the tunnel.

With these challenges in mind, the team at Johnson Poole & Bloomer and DCTT utilised a smaller watercraft to carry a cross-tunnel support beam, upon which the Leica RTC360 laser scanner could be mounted at different points throughout the tunnel. Not only did this allow for the maximum amount of data to be captured, but also removed the risk of the scans being corrupted by movements from the boat.

The Singing Cavern, the deepest publicly accessible section of the tunnels, had been experiencing some changes in its environment; dampness, shale movement and some rock falls. The usual inspection methods used by the trust were not able to capture this information. A pilot scan project in January 2019 gave the details and evidence required to expand the project to obtain a much better understanding of the tunnels and their stability and potential changes.

Due to the system being flooded, evidence of a fall can be quickly lost underwater – DCTT needed a more robust approach to fully line up the underground system with the above-ground location.

Simplicity in design

With the ability for mass data collection through a range of various reality capture equipment, such as terrestrial laser scanners, unmanned aerial systems (UAS), handheld laser scanners and close-range photogrammetry, a modern approach was applied to deliver a product to the trust that had never been explored. With the caverns being a complex environment to map, it was decided to supplement traditional methodologies with reality capture equipment to create a product with various outputs.

The team was able to address the survey control, high precision monitoring, topography mapping, measured building surveying, handheld scanning areas of the tunnels and caverns, and the fast terrestrial-based scanning of the caverns, tunnels and buildings. All results were brought together in one piece of software to create the required product.

Of all the features in the products used on the project, the one feature that was highlighted above all is the approach to simplicity in design. This can be seen with the RTC360 and the BLK2GO handheld scanner where the learning curve in its application on site is minimal, with little to no requirement to learn the interface and equipment workflow. Register 360 was used to process the reality capture datasets from the various equipment in order to create the required outputs.

The site includes a canal, tunnels, underground caverns and abandoned mines.

Implementation

The Leica TS16 and GS18T were used to create the control network in two locations that were able to tie into the underground environment using circular prisms and 4.5" black and white tilt and turn targets. The BLK2GO was used to scan the woodland topography above the tunnels and caverns, as well as sections of the tunnels and within the portal building.

With the unique challenge of scanning on water, the RTC360 was implemented throughout the tunnels on a prop and clamp system, and through the caverns on fixed pillars and tripods. The portal building was also scanned, both internally and externally with the RTC360 on a telescopic tripod system.

Finally, the P40 and NCTECH iStar were mounted on fixed pillar positions throughout the biggest cavern, utilising the survey traverse functionality in order to accurately capture the required data through the pre-survey control, as well as rapid collection of HDR images through the NCTECH camera solution. Equipment suppliers SCCS conducted various site and virtual meetings before the project began to discuss which solutions could be used and the benefits of the different solutions within the various unique and testing environments. Site visits ensured that the solutions that had been hypothesized would be suitable for when the project started. This enabled all parties to resolve any teething problems before the work commenced.

The various solutions implemented enabled the environment to be mapped and viewed spatially in a completely unique way, allowing for reliable data analysis and dissemination. The client was extremely impressed with information picked up and displayed from the HDS solutions that detailed the underground environment that had otherwise never been seen, allowing questions to be answered straight from the software that had been elusive beforehand.

The survey solutions opened previously unavailable opportunities and a plethora of benefits for DCTT to explore uses of the data that can supplement current and future operations, such as health and safety flythroughs, augmented and virtual reality, monitoring and conservation recording. DCTT will continue to use the equipment and technology as an integral part of its ongoing inspection approach.

James Phillips, Field Sales Representative and Phil Marsh, UK Sales Manager for Reality Capture, SCCS, with James Deacon, Geomatics Surveyor, Johnson Poole & Bloomer, and Traci Dix-Williams, Chief Executive Officer, Dudley Canal and Tunnel Trust

www.sccssurvey.co.uk https://jpb.co.uk www.dudleycanaltrust.org.uk