Laser Scanning

Scanning brings new light to a historic Dutch village

A REALITY capture specialist in the Netherlands has added high-precision scanning services for its architecture clients. Paul3D has adopted laser scanning to save time and costs for as-built surveys of a historic village to assist lighting design. Where few record drawings exist for structures that date back to the 1600s, manual as-builts could have taken many months, but with the right scanning device, high-fidelity 3D models can be produced in only a few days.

Shedding light on a historical village

Franeker is one of 11 historic towns in the northwest province of Friesland. Founded in the year 800, Franeker is home to many iconic buildings; cathedrals, university and civic buildings and a famed planetarium built in the 1800s. Architect Provex was seeking to create a full 3D model of the historic centre of Franeker to be used for the design of new lighting to accentuate the beauty of the town’s architectural treasures. Using the Trimble X7 scanning system to create point clouds, Paul3D set about doing some scans to test its feasibility for such applications.

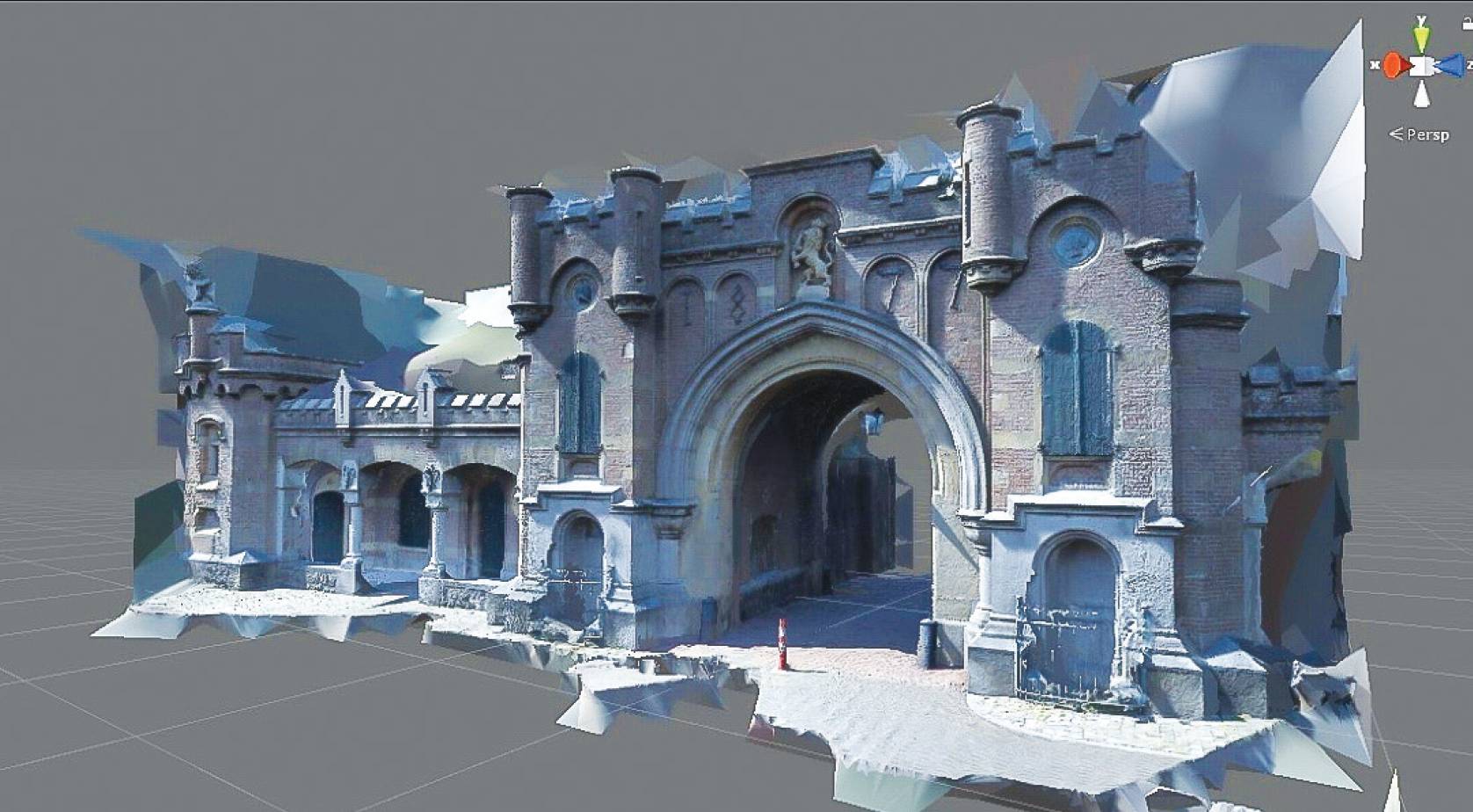

For a proof-of-concept, the Utrecht Gate of the 16th century Naarden Fortress in the Gooi region of the Netherlands was selected. Combining scans from the X7 and photos, a 3D model of the ornate gate was delivered to the client.

|

|

|

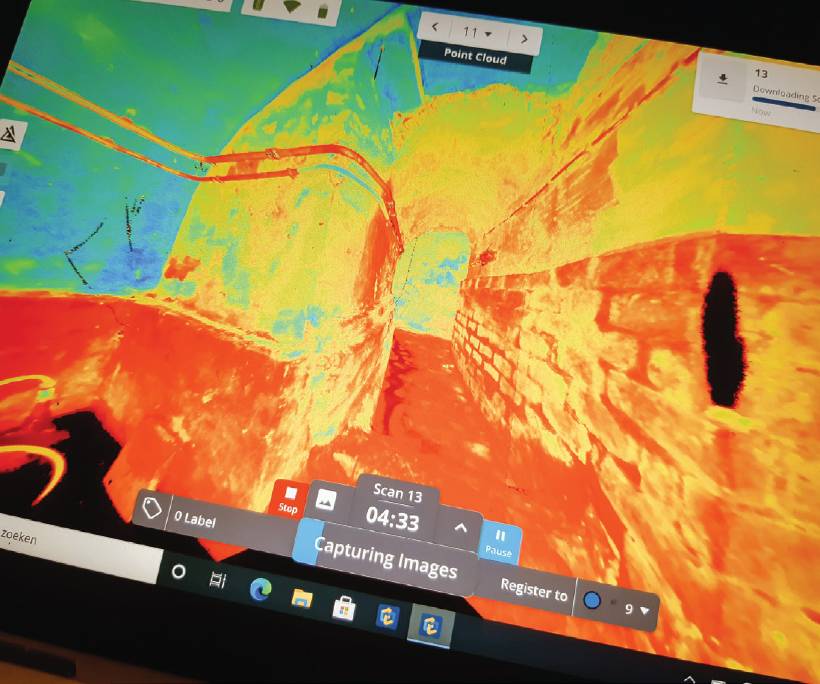

125 scans were carried out in Franeker over two days; followed by 5,000 photos taken with a digital camera which took an additional three days. The scan was delivered as a single cloud, registered in the field in Perspective software running on a tablet that also controls the scanner. The scan and images were processed together by the client and an Autodesk 3DS Max model was created for the lighting designers. Without scanning, the client would have needed to look for drawings of the buildings and there are not many of those for such old structures. It would have taken months to measure by hand and total station to build a model for the lighting designers.