Infrastructure procurement

David Kinlan, Director, and Kenneth Willems, Director, Inframara BV

COMPLEX construction projects that use traditional procurement practices are often impacted by significant cost overruns and delays. The ‘business as usual’ model of procurement is usually driven on a pure transactional basis by the client seeking the lowest price from tenderers for their project – using either a completed design or for tenderers to price the client’s requirements on a design and construct basis but when the design solutions may have already been fixed during the permitting and approval process.

With design and construct, using a traditional tender process and with a ‘locked-in’ design, there is little scope for innovation, alternative designs, methods of construction and cost savings as usually the client’s requirements were fixed. Contractors have little option but to follow the design as approved in the permitting process.

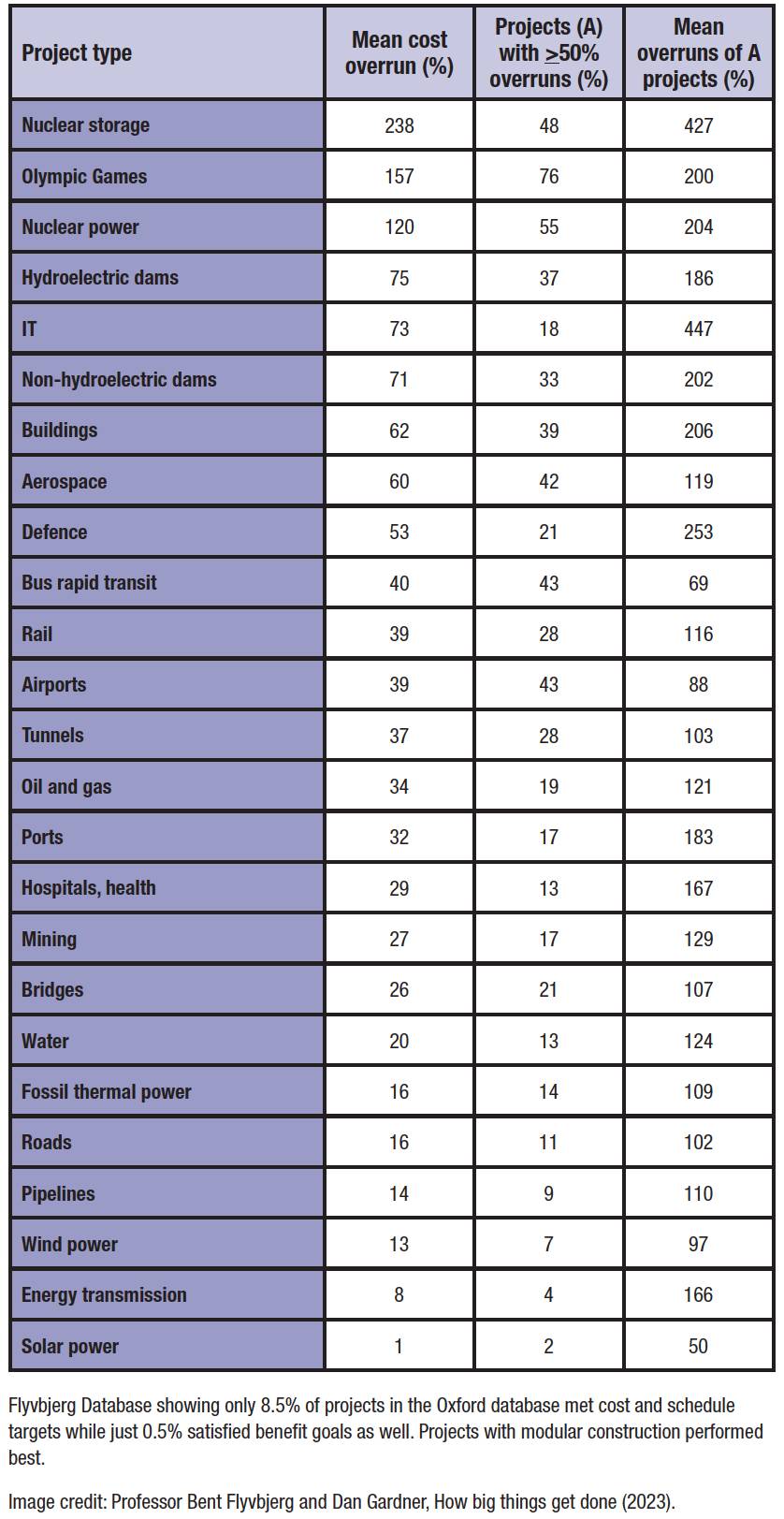

The traditional procurement approach invariably leads to cost and time overruns during project execution. The causes of these overruns have been studied extensively, such as by the Global Construction Disputes Report (Arcadis, 2022), and Professor Bent Flyvbjerg (2023).

A detailed study by Professor Bent Flyvbjerg of some 16,000 major projects from large buildings to bridges, dams, power stations, rockets, railroads, information technology systems and even the Olympic Games, revealed a massive project management problem. Only 8.5% of those projects were delivered on time and on budget, while a mere 0.5% were completed on time and on budget and produced the expected benefits.

In ‘How big things get done’ a book by Prof. Bent Flyvbjerg and Dan Gardner (2023) the authors give insights as to how to successfully plan and deliver projects on any scale – from home renovation to space exploration.

With design and construct, using a traditional tender process and with a ‘locked-in’ design, there is little scope for innovation, alternative designs, methods of construction and cost savings as usually the client’s requirements were fixed.

This has had an effect on some major contractors some of whom have exited parts of the infrastructure market where they perceive exposure to high risk projects whilst other major players have gone insolvent as they struggle with rising costs.

These events and challenges are being felt post-pandemic and construction industry parties and clients in particular are looking to alternative approaches for potential projects. Alternative project delivery using methods such as early contractor involvement (ECI) is increasingly being seen as a valid alternative to drive solutions at an early stage in a projects development thereby ensuring a project is delivered within budget and completed on time.

ECI is a concept that strives to involve the contractor collaboratively at an early stage of a project’s development to mitigate or otherwise eliminate those risks. In August 2022, the World Association for Waterborne Transport Infrastructure (the PIANC), published the report, ‘A framework for early contractor involvement in infrastructure projects’, to help industry practitioners in choosing and best implementing the method. The report was followed by well attended international ECI conference in Brussels on 6 October 2022.

The PIANC report states that the definition of ECI is a strategy initiated by infrastructure owners (clients) towards main contractors and optionally expanded to consultants, stakeholders and subcontractors. The purpose being to optimise values in project delivery and objectives, through their participation and knowledge sharing in stages of project planning and design prior to project execution.

Alternative project delivery using methods such as early contractor involvement (ECI) is increasingly being seen as a valid alternative to drive solutions at an early stage in a projects development thereby ensuring a project is delivered within budget and completed on time.

The PIANC report was published in August 2022 and at some 183 pages, it provides a detailed introduction into the understanding and the application of ECI in waterborne transport infrastructure projects, however, it can be used for all infrastructure projects both large and small. It is the only comprehensive guidance document available on the subject of ECI in the international infrastructure industry. It offers a practical approach to all industry practitioners to assist in the application of ECI in infrastructure.

The report also identifies that the hallmarks of successful ECI process, which have been established over many years, such as dealing with good faith, transparency, equal treatment of all parties, fairness, clarity through clear rules of engagement, confidentiality and protection of intellectual property. The stated aim of the report is to further promote and support the use of ECI in the global construction sector.

This is supported by the Organisation for Economic Co-operation and Development (OECD) who recently met at a conference in Paris to identify how to provide guidance to industry practitioners in the application of ECI for the betterment of the industry as a whole. In the UK, Hong Kong, and in some other countries, the NEC4 contract is being increasingly used and offers ECI as a secondary option (X22) available for use with the NEC4 contract (options C or E).

The parties enter into a single two-stage cost reimbursable contract to collaborate in developing the project, including design and planning for construction (stage one), before progressing to the main construction phase (stage two).

The NEC4 X22 option allows for a collaborative relationship between the client and contractor, with a focus on achieving project objectives and delivering value for money. The contract is flexible and adaptable to different types of projects and procurement methods, and its focus on collaboration and risk management makes it a suitable option for clients and contractors looking to implement ECI in their projects.

ECI is a concept that strives to involve the contractor collaboratively at an early stage of a project’s development to mitigate or otherwise eliminate those risks.It is important to note that the NEC4 X22 is not the magic bullet ‘fit all’ solution and while the principles of ECI may be universal, the specific practices and methods for implementing ECI can vary greatly depending on the region and industry.

To ensure success, clients and contractors should adopt where possible the best practices and lessons learned from previous ECI projects in their specific region and apply them to their current project, while also considering the unique local conditions and major project challenges. This can include factors, such as cultural differences, regulatory requirements, design development, geotechnical risk and market conditions such as the availability of resources.

By taking a localised approach to ECI, clients and contractors can tailor their project to the specific needs and constraints of their region, leading to a more efficient and successful outcome.

Permitting and constructability reviews

Another key aspect is the way that ECI can ensure that the client’s original budget and concept design for permitting and environmental approval purposes can be ‘reality checked’ by potential contractors without the time and expense of going to tender with a complete design. It is a misconception to think that ECI is solely a one-on-one process with a single bidding contractor. Having a competitive ECI process is still achievable and the PIANC report provides helpful guidance on how best to do this.

Clients are continually facing increasing technical complexities, increasing regulatory and environmental restrictions coupled with tremendous internal and external pressures to deliver projects on time, within budget and with unchanged scopes. With multifaceted infrastructure, the permitting process is recognised as being a complex and time-consuming constraint to get a project to market.

The permitting process can take many months or even years from the start of the application process. Decisions at an early stage as to how the project is to be constructed and the choice of equipment and the manner in which material is dealt with and any environmental impact, can have significant time and cost impacts. This is where the involvement of an ECI contractor can have direct and tangible results.

In the UK, Hong Kong, and some other countries, the NEC4 contract is being increasingly used and offers ECI as a secondary option (X22) available for use with the NEC4 contract (options C or E).One author has been involved with a project where a client undertook an extensive regulatory and permitting process, which involved addressing government bodies and key stakeholders concerns, to allow drilling and blasting, as the client considered the material to be removed was too strong to excavate directly. The contractor who was awarded the project elected to excavate the material using a powerful excavator, negating any need to drill and blast.

The operation of the excavator was ultimately successful and any need to drill and blast the material was avoided, as the excavator worked under existing permit approvals. In retrospect, the involvement of an ECI contractor in the early stage of the permitting application process would likely have revealed this and so avoided a lengthy and expensive permitting and approval process based on drill and blasting.

Constructability is where construction knowledge is applied during the early stage of a project where errors and omissions in the permitting and contract specifications can been minimised to enable the contractor to construct a high-quality project that is biddable, buildable and executed using best industry practices. As with the regulatory process, this is where the input of an ECI contractor can have direct and tangible results.

A constructability review process carried out by an ECI contractor is designed to help improve the level of constructability of a project. The most important benefits expected from the review process are the achievement of an efficient project development process and the realisation of a cost-effective project.

The authors recent experience for the Sydney Harbour Tunnel is that based on a single solution chosen as part of the regulatory process the client insisted that only one form of construction using immersed tunnel elements was the preferred and only method. Alternative solutions were not allowed and a conforming bid had to be submitted. The mandated method would involve marine operations laying immersed tunnel elements in a dredged trench in the middle of the iconic Sydney Harbour.

The logistics of such an operation were significant and expensive due to the projects location and environmental groups and stakeholders were concerned about the environmental impact. The most obvious and cost-effective method was using a bored tunnel as used elsewhere on other projects in Sydney. A constructability review by an ECI contractor could have helped in the client decision-making involved at an early stage in the clients’ permitting process rather than going to market and the tenderers pointing out that the mandated construction method was not the best option.

As it was one of the tenderers ignored the ban on alternative solutions and submitted an unsolicited proposal which was cheaper and had minimal environmental impact. This was ultimately accepted by the New South Wales Government, but regretfully many tenderers valuable resources were tied up on submitting proposals for a mandated but flawed solution.

While constructability reviews are effective over a broad range of project types and provide the benefit of allowing multiple functions to view the overall project as it develops, it should be realised that the ECI contractor will have gone into some effort and cost of conducting reviews, albeit for both permitting and/ or constructability and documenting their results. This should be compensated.

Therefore, the decision regarding the number of reviews and the period of involvement of an ECI contractor is a trade-off between the expected benefits and the expected cost of these reviews.

Establishing trust and rapport with your ECI Contractor

“Trust comes on foot, but leaves on horseback” – Johan Thorbecke, a Dutch politician, made this quote back in 1848. It is interesting to consider his words and how it succinctly describes the essence of trust and its vulnerability. Trust in business is not just important, it is essential.

To build trust takes time and it can be gone quickly, and perhaps forever if it is violated. Trust is essential for any kind of business relationship and the need for it in a construction project is no different. Perhaps it applies to a lesser extent for a one-off relationship than for a more collaborative relationship that ECI tends to offer.

ECI in infrastructure projects brings many direct benefits such as cost savings, better communication and collaboration, innovation and creativity, and positive relationships between all parties with a decreased risk of disputes and claims.In collaborative ECI relationships, you need to be able to rely on what your chosen partner is saying and your partner must be able to rely on you. Trust in a collaborative relationship is always two ways: it is impossible for you to trust your partner while your partner does not trust you. Without this mutual vulnerability, trust is impossible to build on and can thwart a successful collaborative partnership.

Building trust takes time and requires constant positive reinforcement. From the client side, it also involves accepting that the contractor should have the ability to make a reasonable margin on the project and having a balanced project risk profile. ECI contractors have valid concerns about the confidentiality of intellectual property and can feel vulnerable with complete exposure of sensitive commercial pricing information.

The commercial challenge with a client taking an ECI contractor on board on a one-to-one basis is obvious; how to ensure competitive pricing? Although nothing will completely mitigate that challenge, building openness and freedom of communication between the partners at an early stage is vital.

Generally the core means to reduce that risk/concern is using competitive dialogue with more contractors in the early stage. This will lead to selecting the contractor the client feels most comfortable with.

Conclusion

ECI in infrastructure projects brings many direct benefits such as cost savings, better communication and collaboration, innovation and creativity, and positive relationships between all parties with a decreased risk of disputes and claims.

In infrastructure projects, ECI can achieve direct benefits when developing project budgets when preparing constructability reviews and construction risk assessments. It also has been used effectively during the regulatory and permitting stage of a project.

Parties need to be open and mutual trust needs to be built in a collaborative relationship. With it comes vulnerability. Without acceptance of this trust is impossible to build on and lack of trust can thwart a successful collaborative partnership. ECI is becoming increasingly popular as an alternative procurement method and is seen as a key way to improve the construction process and mitigate the unique challenges of any project.

David Kinlan, Director, and Kenneth Willems, Director, Inframara BV